In an auto manufacturing first, Tesla has started building Model Y bodies with two giant single casting pieces for the front and back of the electric SUV.

Tesla has been preparing to start production of the Model Y at two new factories, Gigafactory Berlin and Gigafactory Texas.

CEO Elon Musk has been hyping the new Model Y to be built at those factories as “a revolution in auto body engineering.”

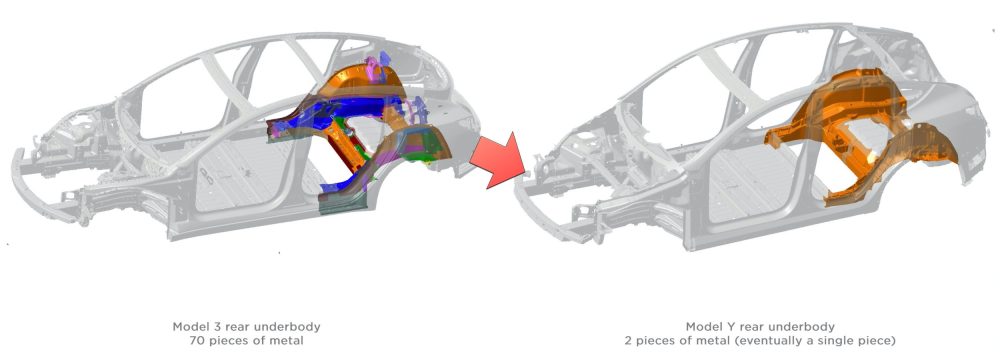

He was referring to Tesla using mega-casting parts to have single body pieces for the rear and front of the electric SUV.

Over the last few years, the automaker has been heavily investing in casting and alloy technology to enable larger casted parts that have the capacity to greatly simplify manufacturing.

The company even acquired several units of the biggest casting machines in the world.

Tesla has already been producing the Model Y with a single rear body piece that replaced 70 different parts in the vehicle.

Earlier this year, a picture of the first single front casting part of the Model Y produced at Gigafactory Texas leaked.

It appears that a few months later, Tesla confirmed that it is now producing the Model Y body with the two parts.

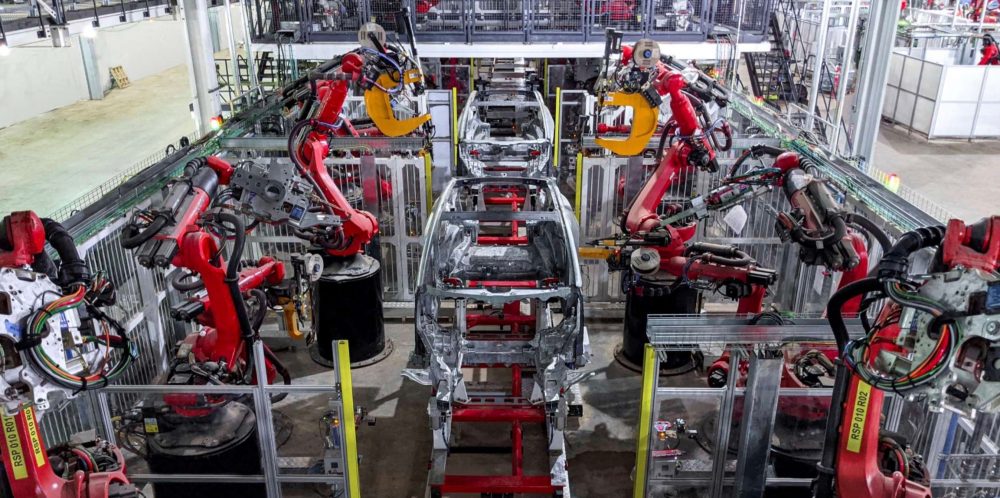

In a picture released in its Q2 2021 financial results, the Model Y body production line shows new bodies going through the line:

It apparently went unnoticed, but a former Tesla employee with knowledge of the Model Y body was able to confirm from the picture that these bodies feature both single-piece front and rear casting parts and reached out to Electrek.

This is a first in auto manufacturing, and if successful, it could change the game.

A source familiar with Tesla’s body engineering listed some of the many benefits of such a design:

You save on new factory space, CAPEX (eliminate hundreds of welding robots & stamping machines), better NVH, lighter, increased range, make manufacturing simpler by reducing the number of stamping & welding, savings from eliminating tooling/maintenance cost of welding & stamping, vertical integration, better supply chain control, and so many other benefits.

Tesla has been wanting to go a step further and joined those two parts with a structural battery pack powered by its new 4680 battery cells unveiled last year.

However, the automaker has lately indicated that the integration of the new cells and structural battery pack might not be introduced with the start of Model Y production at the new factories.

Tesla has been guiding a start of production at Gigfafactory Texas and Berlin by the end of the year.

Electrek’s Take

This is an impressive achievement.

Tesla naysayers are quick to say that any other automaker can do it and they simply don’t because of the consequences when it comes to servicing.

It’s true that there are implications on body repairs when using such large casting parts and it remains to be seen what the cost of repairs would look like, but I’m not so sure that any other automaker can achieve this.

Casting large parts is hard and we believe that Tesla didn’t just order the biggest casting machines in the world to achieve this, but they also developed a custom alloy with the joint Tesla-SpaceX material team to make such large casted parts possible.

I think the Tesla-SpaceX material science team is not to be underestimated.

We expect Tesla to release more details about Model Y body production at Gigafactory Austin on Thursday when Tesla will hold its shareholders meeting at the new factory.

Subscribe to Electrek on YouTube for exclusive videos and subscribe to the podcast.

Author: Fred Lambert

Source: Electrek