Lithium is a vital component of EV batteries, and Winnipeg, Canada-headquartered Snow Lake Lithium says it’s committed to operating a fully renewable and sustainable lithium mine. What does that mean?

Sustainable lithium mining in North America

North America is home to just one active lithium mine, the Silver Peak mine in Clayton Valley, Nevada, and only recently, due to rising electric vehicle demand, has the lithium mining process entered mainstream dialogue, since it’s vital for EV batteries.

Snow Lake Lithium’s (Nasdaq: LITM) mine is at Snow Lake in Manitoba (pictured above). Australian exploration company Nova Minerals Ltd. acquired the lithium-rich land in 2016, and it remains a majority shareholder to Snow Lake Lithium, which was formed in 2018.

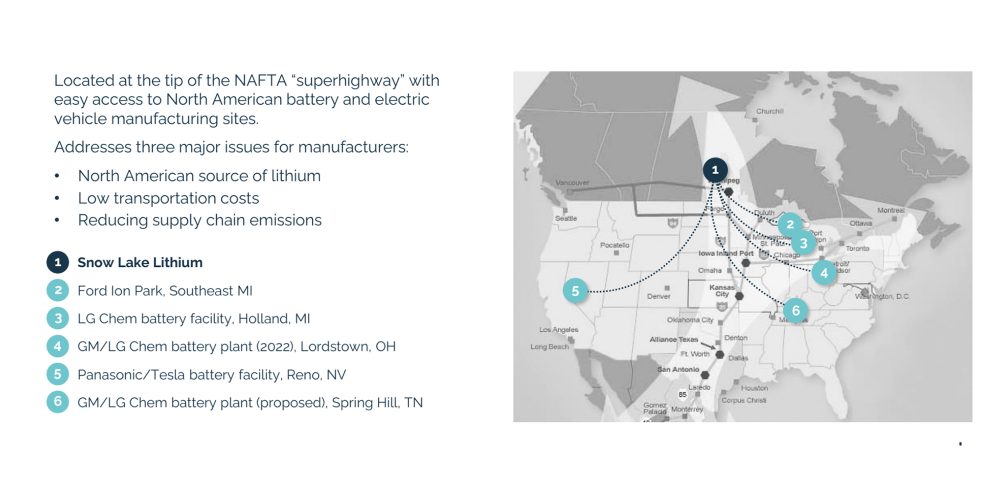

Snow Lake Lithium is developing the world’s first all-electric lithium mine. It claims it’s “perfectly positioned to supply a critical resource to the North American EV and battery market” due to proximity to key railways that provide direct, efficient access to North American battery and EV manufacturing sites, thus reducing supply chain emissions and timing issues:

Snow Lake will also have access to a 98% renewable hydroelectric power, and will have no trucks or diesel emissions on site.

Two lithium extraction variations are currently used – hard rock and brine – and Snow Lake says it will use the hard-rock mining process to source lithium hydroxide for EV battery production. Hard-rock extraction uses significantly less water and energy in production, whereas the long-term effects of brine mining remain ambiguous and require a diversion of water.

Electrek asked Snow Lake Lithium’s CEO Philip Gross about what successful sustainable mining will looks like, not only for the company, but also for the electric vehicle supply chain.

Electrek: Where is Snow Lake in the sustainable mining process, and what will success look like?

Philip Gross: We’re making significant progress on our environmental and feasibility studies and are on schedule to accelerate the project to permitting and commercial production in 2025. Our surveys have explored only 1% of our more than 55,000-acre site in Manitoba and suggest that a fully functioning mine will produce 160,000 tons of 6% lithium spodumene every year over the course of a decade.

We are facing the biggest industrial pivot with electrification since the construction of the railways, and yet, the raw materials necessary for its success are being sourced abroad. A fully integrated lithium production process does not currently exist in North America. Success for Snow Lake Lithium is standardizing energy sustainability in mining, while simultaneously advancing the domestic lithium supply chain.

Electrek: What are the challenges that Snow Lake, and sustainable mining in general, need to overcome?

Philip Gross: The biggest challenge and opportunity to help ensure more sustainable mining for lithium is to bring the battery refinement processes close to the actual source itself and minimize the shipping process and global logistics impact of moving the produced minerals to the final auto and transportation facilities themselves.

Currently, there are fleets of cargo ships transporting needed lithium batteries and core materials between North America and China, and all over the globe. Being able to source and refine more effectively within core regional EV ecosystems is paramount. Not only to ensure that the automotive and other industries have more reliable access to core materials, but also to dramatically reduce the global carbon footprint and waste of shipping.

Manitoba offers access to quality lithium, a supportive community and cultural respect, and expertise in effective mining techniques. It also offers immediate proximity to rail shipping yards that can bring our sourced lithium directly to Detroit and throughout the US in days.

Electrek: You are calling for the creation of a complete electric vehicle ecosystem across North America. What does that look like?

Philip Gross: We are facing an existential threat to the North American automobile industry due to the lack of raw materials necessary for electrification. We must secure a seamless lithium supply chain from rock to road to ensure our existence in the electrified future. This rock-to-road strategy must be pieced together from scratch to enable a truly seamless supply chain powered by raw materials, such as lithium.

Currently, the EV ecosystem is being built from the top down with consumer demand driving its rapid growth. In response, OEMs are expediting product development and subsequentially pressuring battery manufacturers to build gigafactories. However, we are severely lacking in the raw materials necessary to sustain these manufacturing operations.

At Snow Lake, we are aiming to fill this gap by operating a fully integrated processing strategy that delivers domestically mined lithium to the North American automotive market in a fully sustainable and environmentally conscious supply chain.

Raw materials are the foundation of the EV ecosystem. As an element, lithium is plentiful. The challenge is bringing lithium to the market. We must expand North America’s battery infrastructure while meeting our emission goals to ensure the future of our domestic EV market.

Photo: Snow Lake Lithium

Philip Gross serves as the CEO and chairman of the board for Snow Lake Lithium. Philip brings more than two decades of experience advising resources and mining operations as a recognized mining sector leader with expert knowledge and relationships within the global commodities and investment communities.

UnderstandSolar is a free service that links you to top-rated solar installers in your region for personalized solar estimates. Tesla now offers price matching, so it’s important to shop for the best quotes. Click here to learn more and get your quotes. — *ad.

Subscribe to Electrek on YouTube for exclusive videos and subscribe to the podcast.

Author: Michelle Lewis

Source: Electrek