While its initial production will begin in the UK, the Arrival Van will eventually be produced on US soil as well. In the meantime, we were able to go see the commercial EV up-close in the Big Apple and learn more about its progress first hand from Arrival President Avinash Rugoobur and CEO of Arrival North America, Mike Ableson.

Arrival is a growing EV startup focused on clean, urban-centric mobility whose unique production strategy could very well become a new standard for sustainable and cost-effective EV manufacturing. Since being founded in 2015, the company has introduced an all-electric passenger bus, a delivery van, and a rideshare-specific car designed alongside Uber.

Headquarters in London and Charlotte, North Carolina, give Arrival a production advantage in two large markets, although all of its R&D and design currently takes place in the UK. What may be most unique about Arrival however, is its microfactory approach to EV production.

Instead of dishing out hundreds of millions of dollars on bespoke automotive facilities, Arrival buys or leases new and existing industrial facilities and installs its own assembly cells – cells that can be quickly and efficiently implemented and continuously optimized for maximum efficiency.

Later this year, these ultra-efficient assembly practices will be applied to both the Arrival Bus and Arrival Van. Although US assembly of the Van will begin after production in the UK, we were able to see a beta prototype close up and get a company update from two Arrival executives.

Updates on Arrival before US Van production in Q4

Electrek was fortunate to take a trip out to NYC this week and see the Arrival Van prototype in the US before production begins overseas in Q3. Additionally, Seth and I were able to visit with Arrival President Avinash Rugoobur and CEO of Arrival North America, Mike Ableson, to ask as many questions as we wanted.

They are obviously quite excited that one of their first ever EVs is finally coming to fruition and spoke quite candidly with us about the company’s progress, goals, and how it hopes to inspire a paradigm shift as to how the automotive industry produces electric vehicles. Lots to share here, but let’s start with the star of this particular US visit, the Arrival Van.

US to see Arrival Van production before year’s end

As you can see from the images above, the beta prototype of the Arrival Van very closely resembles many of the renderings and early images we have seen. Even close-up, it looks a lot more groomed than other prototypes we’ve seen, especially for a beta.

Arrival’s sleek, minimalist approach to design is apparent inside and outside of the Van from its monotone exterior to its simplistic driver’s side. Ableson explained to us how the exterior is made of swappable composite panels (although he said they shouldn’t need to be replaced because they are so strong.) The team passed around a sample of the composite, and I felt like the guy in Napoleon Dynamite trying to break the “Nupont fiber woven bowl,” – I couldn’t do it.

In addition to its strength, the composite material can be dyed to any single color, alleviating any need for special foundations or pits for painting – a large and less environmentally-friendly footprint on traditional assembly lines. Entering the cabin, we were surprised to learn that the grey, carpet-like interior is made from the same composite material, again adding to the simplicity, sustainability, and overall recyclability of this EV.

We’ve previously reported Arrival’s order for 10,000 Vans from UPS and Ableson walked us through a lot of the design elements implemented to both support and optimize a delivery driver’s day-to-day. For example, the lower floor sits at average curb height, allowing for less of a step in and out of the van, while the driver’s seat has been set at a height that not only provides comfort, but less movement between standing and sitting. This is crucial as drivers will undoubtedly be switching from a sit to standing all day, every day.

Arrival is working on other features such as automated doors than more softly open and close as the driver approaches – reducing repetitive motions on a driver’s arms and shoulders – while also removing some of the impact the continuous slamming of a door may have on the mechanism itself.

The driver’s touchscreen is large and centrally located, containing Arrival’s proprietary fleet software, and will continuously gather and analyze data to support further optimizations for commercial customers. Overall, it’s a sleek and efficient approach to an ever-growing segment of last-mile delivery vehicles that are going electric at an impressive rate.

What’s next for the Arrival Van

According to the North American CEO, the company is currently developing gamma prototypes of the Arrival Van in the UK, and we may be able to catch a glimpse of one in the US soon – keep an eye out for that.

UPS remains a big part of the design process for its upcoming order, and Arrival will be able to manufacture its composite panels in the parcel service’s recognizable shade of brown. According to Ableson, pulling off UPS’ unique, dark silver wheels will be a task in-and-of itself, but Arrival is up for the challenge.

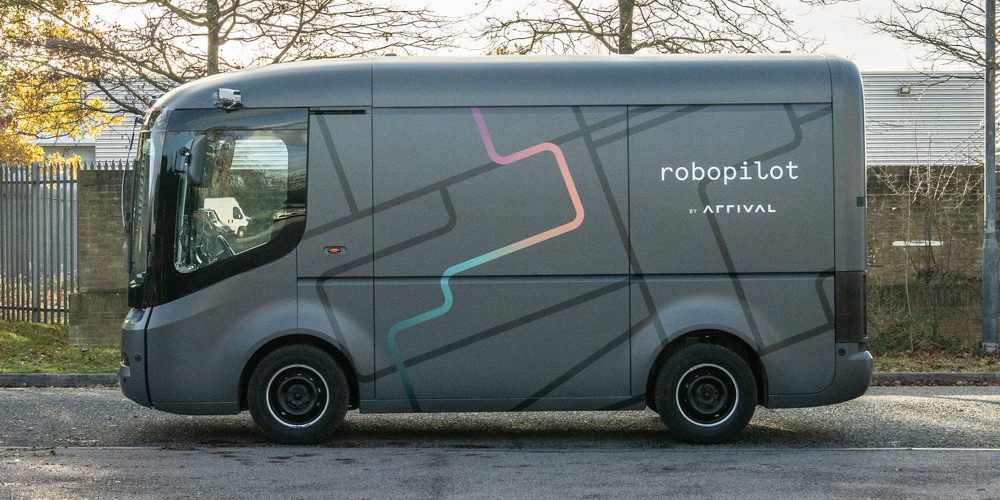

As you may recall, Arrival has been working on autonomous rides with its Van in the UK through its Robopilot program. The program is continuing to progress overseas, and we could eventually see autonomous Arrival Vans in the US.

During a breakfast with Mike Ableson, he told me that Arrival is exploring depot automation in the US, which entails autonomous Vans navigating geofenced fleet depots. Since these EVs are geofenced and will not be on roads, there are far less regulations to abide by, allowing for quicker integration.

The Arrival Van is still on schedule to begin production in the UK in Q3 of this year, followed by US production at its Charlotte microfactory in Q4. The initial model will soon be joined by two larger Vans as well, allowing for more platform space to implement additional battery modules too.

Other Arrival updates

Arrival’s main focus right now is getting its microfactories to production in the UK and US, beginning with the Arrival Buses and Vans. From there, the company can continue to optimize its production practices to minimize time and costs, then its copy paste anywhere and everywhere.

This future also includes Arrival’s previously announced North Carolina facility to build its High Voltage Battery Modules (HVBMs). Ableson told us that Arrival is currently sourcing 18650 lithium-ion cells from LG chem and implementing them into its unique modules. Since its microfactories are starting on such a small production scale (10,000 EVs a year), Arrival is not currently worried about many of the supply chain constraints that are impeding larger OEMs.

The Arrival Bus remains on track for production and will be produced at the company’s Bicester facility in the UK in Q2 and its Rock Hill, South Carolina microfactory in the US. We’re hoping to visit Arrival’s UK headquarters to see the Bus up-close and do a test drive with the Van. Fingers crossed!

The Arrival Car is currently in the prototype phase and will begin testing this year. During breakfast, I confirmed with Ableson that while Uber is helping design the rideshare EV, it has no exclusive rights to it. So, if another rideshare company, or even a regular consumer were interested, Arrival has no issues selling the car to them.

As Arrival expands its US presence, it’s hoping to give back to its new home in Charlotte, North Carolina and promote sustainability as much as possible. Ableson told me that Arrival is working with the city of Charlotte about the possibility of establishing courses at local colleges to educate the youth about EV manufacturing, hoping to recruit new employees to come work at its microfactories.

Additionally, we learned that Arrival strategically placed its Charlotte HQ near the light rail line, hoping to hire locals that don’t have to drive to work. Arrival’s President, Avinash, told us he does not have a car, and instead commutes daily by bus. In his words, “What better way to understand what’s working and what isn’t on a passenger bus than to ride it every single day?”

Ableson spoke to me about his love for electric scooters and how he tries to commute on them wherever possible, rather than drive. These practices by Mike and Avinash are a wonderful representation of how granular and holistic the company’s focus on sustainability is, and it was a joy to learn so much from the entire team. Thoroughly looking forward to watching this company grow.

Electrek’s Take

What a cool team overall. Avinash and Mike couldn’t have been more approachable and personable, offering wonderful insight into Arrival’s strategy and the EV industry as a whole. The excitement was palpable throughout the team, as it is on the cusp of delivering not one, but two of its flagship EVs.

I found the Van quite impressive (at least for a delivery vehicle) and believe it could change the landscape, or at the very least, the overall look of delivery vans. That will stem from the microfactory model, which I personally believe is the ace up Arrival’s sleeve.

The prospect of revamping existing facilities you don’t have to necessarily own, without the need for paint pits could be such a game changer. The innovation behind the color and design capabilities of the composite panels might need to be pushed a little further to satisfy customer marketing departments, but trust that Arrival is working on that in the UK.

Avinash told us that he’s sure larger OEMs like Tesla and Rivian are watching Arrival’s microfractory model closely to see if it proves viable. I personally agree with him that more abundant, yet smaller production footprints could completely shift the way we produce vehicles, promoting sustainability through locally sourced raw materials, shorter supply chains (not to mention in-house components), and shorter delivery distances to customers.

On top of all that, the model allows for easier pivots in the assembly line process itself and the potential for continuous optimization. Arrival’s goal is to eventually have one production cell that can produce an entire EV by itself – not just one particular model, either. Multiple Arrival EVs.

Needless to say, we are itching to get inside a microfactory and view the process first hand. Charlotte should be ready for visitors before year’s end, so I’m going to start packing a bag. Stay tuned.

Subscribe to Electrek on YouTube for exclusive videos and subscribe to the podcast.

Author: Scooter Doll

Source: Electrek