VW believes that it can catch up to Tesla where it matters when it comes to electric vehicles: mass production capacity.

The head of VW’s worker union believes that they can achieve a production capacity of 1.5 million electric vehicles by 2023 ‘or sooner’.

With Fremont factory and Gigafactory Shanghai, Tesla has two of the highest producing electric vehicle factories in the world.

Other automakers are playing catch up, but Volkswagen, who has been less shy about converting existing factories to electric car production, believes it can catch up.

Bernd Osterloh, the head of Volkswagen Work Council, told Germany’s Welt that he believes that catch up to Tesla’s planned production capacity by 2023 (translated from German):

“If Tesla builds three factories in which you can build between 300,000 and 500,000 cars, then we’re talking about a number between 900,000 and 1.5 million. We want to achieve that in 2023, probably sooner.”

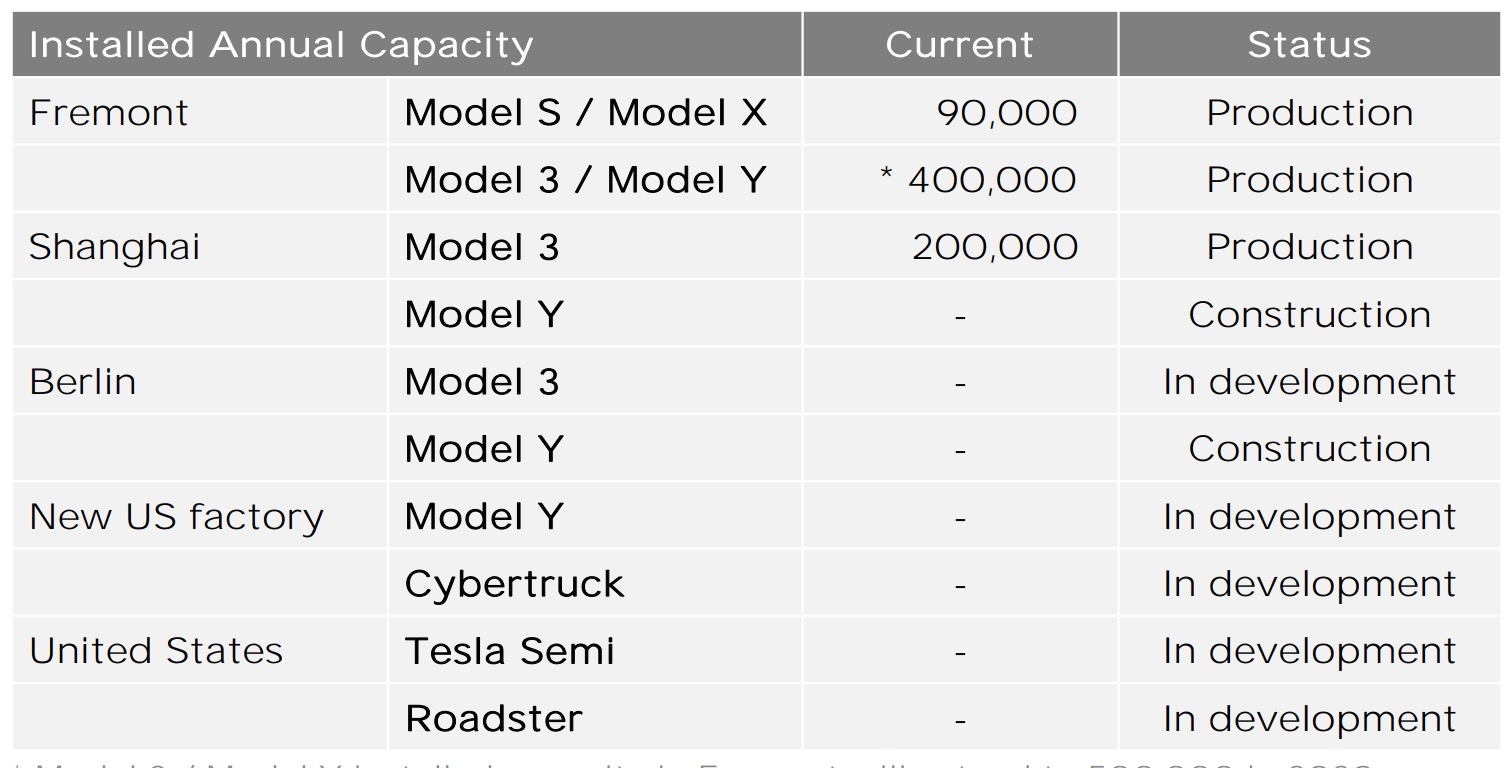

Tesla had a production capacity of 690,000 cars at the end of the last quarter according to its own filing:

But the automaker plans to have a production capacity of 500,000 Model 3 and Model Y vehicles in Fremont by the end of the year.

The production capacity of the rest of the factories in development is less clear, but Tesla is expected to double the production capacity in Shanghai with the introduction of the Model Y next year.

Furthermore, Gigafactory Berlin and Gigafactory Texas are expected to each have total outputs of more than 500,000 cars per year.

It would put Tesla’s total output closer to 2 million vehicles once all projects are completed.

Both factories in Germany and Texas are expected to start production next year, but it will take a few more years to ramp up to full production.

As for Volkswagen, the automaker has converted its entire Zwickau factory to electric vehicle production and it also started to convert its Emden factory to begin electric car production in 2022.

VW is also producing electric vehicles out of a factory in China and it is building a new factory next to its Chattanooga factory in Tennessee to produce electric vehicles.

Osterloh mentioned that the work council won’t be afraid to push for the conversion of their massive facilities in Wolfsburg if they see a need for it:

“There is of course the possibility of converting the Wolfsburg site to electric cars. If the number of combustion engines drops sharply, then we as the works council will demand that we also manufacture a battery-powered vehicle here.”

VW’s Wolfsburg factory has a capacity of over 700,000 vehicles per year and a conversion to electric vehicle production would be a major step for the company.

However, the automaker will also have to secure battery cell supply, which it is trying to do through partnerships with several major cell suppliers and its own effort with Northvolt.

Volkswagen is also creating new EV production capacity through its other brands, like Audi and Porsche.

Electrek’s Take

Without caring for a legacy gasoline vehicle business, Tesla had a massive advantage in rolling out electric vehicles.

The automaker didn’t have to worry about managing a balance between introducing electric vehicles and selling its profitable gas-guzzling cars.

Instead, it could focus on securing battery supply and deploying mass production capacity of electric vehicles.

Most other major automakers are still trying to make that balance work.

I think the Dieselgate scandal snapped Volkswagen out of that.

They saw that they couldn’t just keep pushing the old tech anymore and they had to embrace the future, which is why they were quicker to take riskier moves (at least from the perspective of a legacy automaker) in converting existing factories to electric vehicle production.

While I am not saying that VW can catch up to Tesla in EV production capacity, if any legacy automaker can, I think it’s Volkswagen.

Also, we’ve been hearing VW is going to pass Tesla for quite some time.

Subscribe to Electrek on YouTube for exclusive videos and subscribe to the podcast.

Author: Fred Lambert

Source: Electrek