Tesla’s approach to using giant casting machines, nicknamed Giga Press, to make car bodies with just a few massive casted parts is catching on in the auto industry.

A Tesla supplier says that it is working with about half a dozen other automakers taking the same approach.

Over the last few years, Tesla has been heavily investing in casting and alloy technology to enable larger casted parts that have the capability to greatly simplify manufacturing.

The company acquired several units of the biggest casting machines in the world. They have been deployed at Tesla’s factories in the US, Berlin, and China.

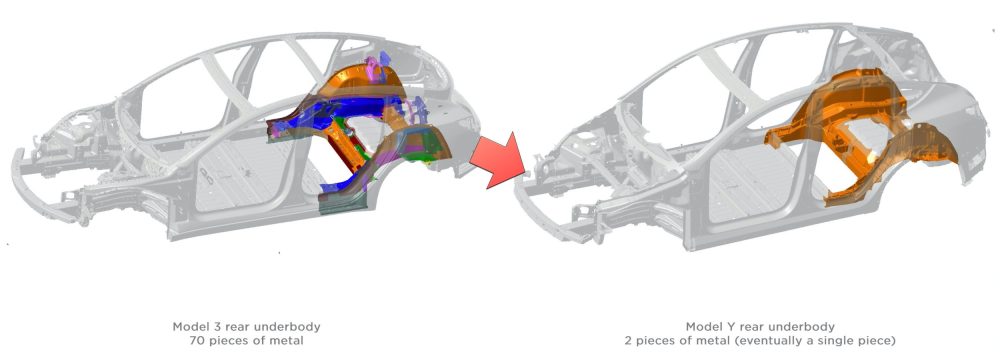

Tesla has already been producing the Model Y with a single rear body piece that replaced 70 different parts in the vehicle.

Earlier this year, a picture of the first single front casting part of the Model Y produced at Gigafactory Texas leaked.

Last month, we reported that Tesla produced the first Model Y with both front and back single-piece casting.

The strategy to greatly reduce the number of pieces to make a car body results in a massive reduction in the complexity of the body line and the capital needed to build the production line.

It also brings weight advantage to the vehicle itself, which in turn can improve efficiency. However, it’s not all advantage.

Some people in the industry have been critical of the cost associated with potential repair in the event of an accident. This is led to questions whether Tesla is leading a new way for the auto industry to build cars in the future or if it was a fool’s errand.

But now it looks like some other automakers are willing to give it a shot, especially in China.

The New York Times published a report on Liu Siong Song, an engineer behind LK Technology, a partner in Tesla’s casting technology.

Liu said that he is working with six Chinese automakers to deploy similar casting technology as soon as next year:

“In addition to Tesla, LK will supply similar giant casting machines to six Chinese companies by early 2022 as more automakers adopt Tesla’s way of making cars, Mr. Liu said.”

However, the engineer suggests that they might run into some issues:

“For all China’s progress, it still has a long way to go. LK hopes to deliver the same types of casting machines to many Chinese companies in the next two years. But some of those companies are struggling to find car designers of the type and talent that Tesla has aplenty. Without the designs, LK can’t deliver the machines.”

Aside from designs, other automakers might also run into some issues with materials.

Tesla has long invested in material science to develop its own alloys to support such large casting parts. The automaker even partnered with SpaceX to share material science talent to develop those alloys.

Subscribe to Electrek on YouTube for exclusive videos and subscribe to the podcast.

Author: Fred Lambert

Source: Electrek