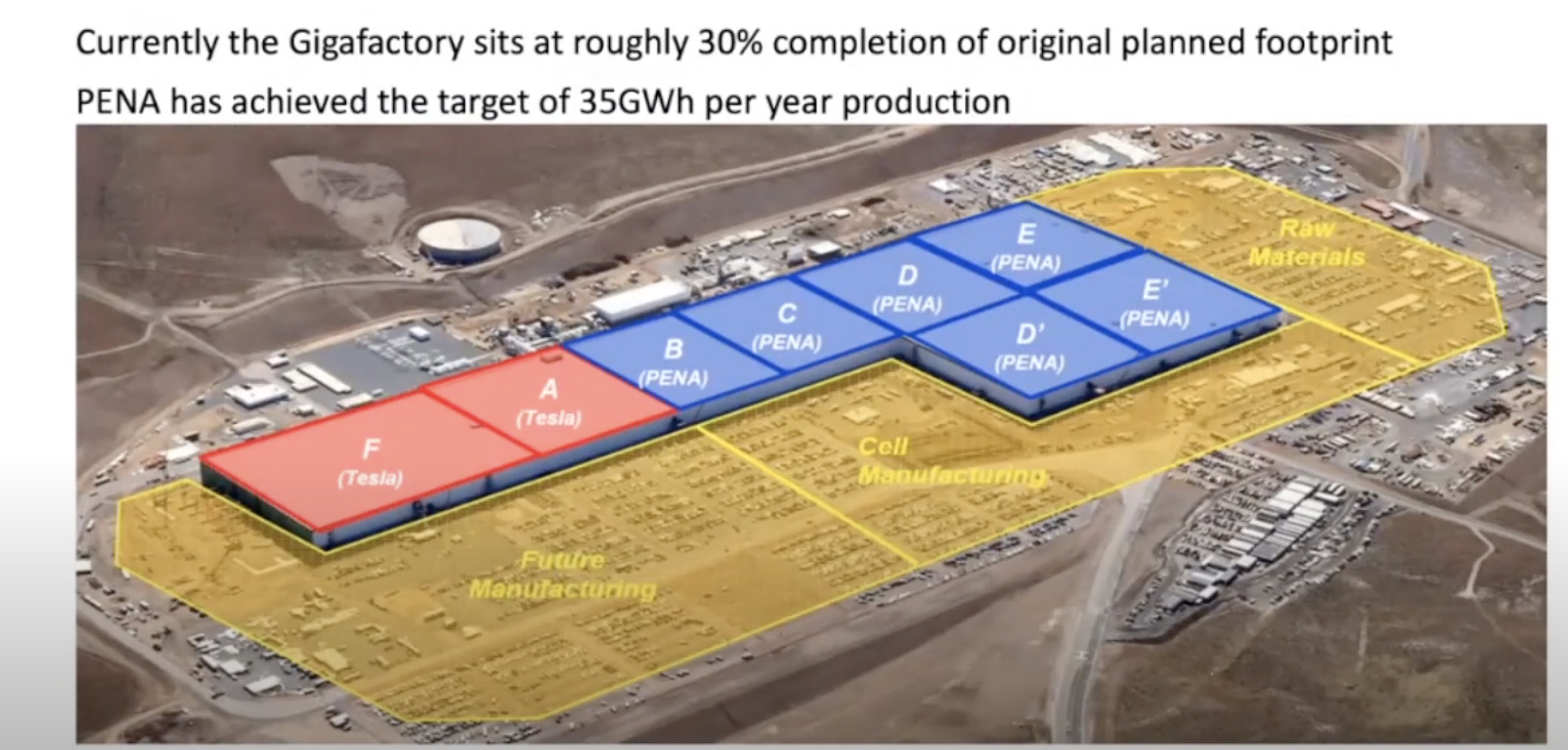

Tesla Gigafactory Nevada is infamously only “30% complete” and it has been that way for the past 3 years.

Here’s what it is supposed to look like and what Tesla and Panasonic are supposed to do with the extra space.

Tesla Gigafactory Nevada was the first major step in Tesla’s effort to secure battery cell supply for its ambitious growth.

The automaker partnered with Panasonic to deploy new battery cell production capacity at the facility and Tesla used those cells to build battery packs for its vehicles and energy storage products.

When originally announcing the plan for the factory, Tesla was talking about the plant producing 105 GWh of battery cells per year and 150 GWh of battery packs per year once completed.

It was supposed to become the largest building in the world.

However, the factory is currently about 30% complete and Tesla hasn’t expanded the facility for years as both the automaker and Panasonic have focused on optimizing the current production capacity.

In a recent talk, Celina Mikolajczak, Vice President of Battery Technology at Panasonic Energy of North America, revealed what future expansions could bring to Tesla Gigafactory Nevada.

Mikolajczak is arguably one of the most knowledgeable people about Gigafactory Nevada having worked for both sides of the plant.

At Tesla, she was a long-time expert in batteries and technical leader in development and validation of li-ion cells for Tesla vehicle and stationary storage applications.

Now she leads Panasonic’s battery technology at Gigafactory Nevada.

The engineer recently gave a talk for the Stanford StorageX International Symposium and released some interesting information.

We reported on her releasing new information about a new battery cell Panasonic is producing for Tesla with a higher fast-charging capacity.

She also released an interesting slide showing the plan for future sections of Tesla Gigafactory Nevada:

As you can see, Panasonic currently occupies the majority of the factory, which Mikolajczak says is deceivingly big due to its 3 stories.

Future expansions show more manufacturing space for Tesla, more battery cell manufacturing space for Panasonic, and additional space to handle raw materials.

She said that Panasonic has now 13 battery cell assembly lines running 24 hours per day 7 days a week and they are now producing over 35 GWh of battery cells per year.

You can imagine that with the extra space they could achieve the goal of over 100 GWh of battery production.

As we reported last week, Tesla is also working with Panasonic to build a new 4680 battery cell pilot production line at Gigafactory Nevada.

Here you can watch the talk in full:

Subscribe to Electrek on YouTube for exclusive videos and subscribe to the podcast.

Author: Fred Lambert

Source: Electrek