EV startup Rivian is racing past many rivals with its all-electric adventure vehicles. Yet, what many may not know is that the technology inside a Rivian is just as alluring as the design. Rivian is using software to gain an advantage over the competition.

Rivian took a page from Tesla in designing and building its electric vehicles from the ground up, with a focus on software.

Although it’s a costly strategy, it has given Rivian an advantage as it scales production. “It’s a fantastic advantage because starting from a clean slate allows us to learn from the successes but also the mistakes of others,” explained Wassym Bensaid, Rivian’s VP of software development.

Bensaid said in an interview with MotorTrend that “having the ability to configure every piece of hardware in the entire vehicle through software was one of the main considerations” from day one.

Rivian consistently pushes updates to its vehicles, adding new features like camp mode and snow mode, navigation improvements, added range, improved ride quality, and more.

As Bensaid explains, building Rivian vehicles as a “fully integrated end-to-end” device is helping it overcome one of the biggest challenges in the industry.

Legacy automakers, including Volkswagen, have learned developing and managing software is critical in the digital era. He said the biggest disruptions in the industry “rely heavily on software, and this requires a fundamental approach” to development.

Software is helping Rivian scale past EV rivals

“It’s a new reality where software is the center of the vehicle experience,” Bernsaid said in the interview.

In the new connected, digital era, “The auto industry has struggled to cope with multiple hardware configurations,” he added.

Meanwhile, Rivian has focused on scalability since day one. Its software has been a “key differentiator” as it expands, according to Bensaid.

For example, all three Rivian EVs run on the same software, the R1T, R1S, and EDV. By running different configurations rather than an entirely new stack, Rivian is streamlining the process.

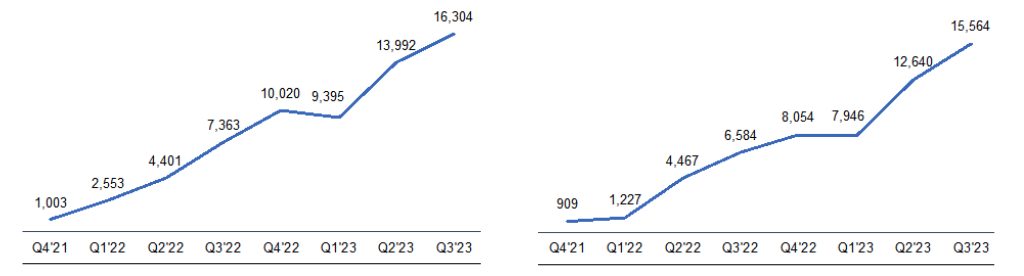

The EV maker delivered 15,564 vehicles in the third quarter, up 24% from Q2 and easily beating expectations. Production also rose 17% quarter-over-quarter to 16,304 units. Following the strong performance, Rivian raised its 2023 production goal to 54,000, up 2,000 from its previous target.

The growth comes amid several automakers, including Ford and GM, delaying EV investments. Lucid also cut its 2023 production target after deliveries and production failed to gain traction.

With most of its software built in-house, Rivian has an advantage. The EV maker can push updates to its vehicles quickly. It also enables Rivian to focus on what matters most to drivers.

“Our vehicle knows the best EV range based on the habits of the driver, the suspension and ride-height position, the driving mode, weather, temperature, and the battery health,” all of which are continuously calibrated through software, Bensaid said.

Electrek’s Take

Scaringe said on the company’s earnings call earlier this week that vertically integrating its in-house computers, software stack, and propulsion system is a “substantial competitive advantage.”

While legacy automakers like Volkswagen have delayed important EVs, including the electric Porsche Macan and Audi Q6 e-tron, over software, Rivian is using it to its advantage.

The company will take what it’s learned in ramping the R1 platform to make its second-gen models even more efficient. Rivian will reveal its R2 platform next year, which will be built at its new facility in Georgia. Rivian will be a company to watch over the next few quarters as it expands the brand.

Author: Peter Johnson

Source: Electrek