General Motors (GM) and South Korean advanced EV battery materials company Posco Future M revealed an additional investment in its new cathode factory in Ontario, Canada, now exceeding $1 billion.

GM plans to enhance CAM supply in North America

The new funding will help increase Cathode active material (CAM) production and the precursor materials (pCAM) needed to produce it in North America.

GM announced plans for the new factory last March, with the initial investment expected to be around $400 million (C$500 million). The facility is designed to manufacture cathode active materials for GM’s Ultium batteries, the backbone of its EV strategy.

CAM is the key raw material consisting of lithium and a secondary metal (or metals) that drive a significant portion of the output and around 40% of the costs of EV batteries. The two primary EV battery cathodes today are nickel-cobalt-manganese (NCM) and lithium iron phosphate (LFP).

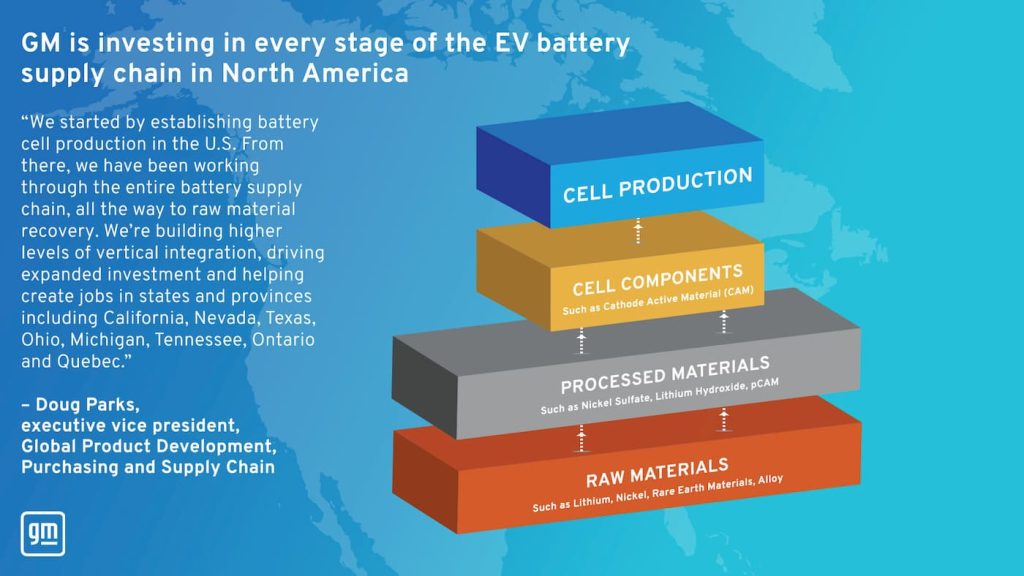

Doug Parks, GM’s executive VP of global product development, purchasing, and supply chain, commented on the new investment, saying:

Increasing CAM production capacity and adding pCAM to our joint venture is another significant step in building a more secure and sustainable North America-focused supply chain to support GM’s fast-growing EV production needs.

With plans for battery cell production to reach at least 135 GWh, or enough to power 1.3 million EVs annually between its three Ultium Cell plants, GM is building out its entire battery supply chain, including raw material recovery.

Vertically integrating the EV battery supply chain

GM revealed its joint venture with LG Energy Solutions in 2019 to produce battery cells for electric vehicles based on its Ultium platform.

Ultium Cells began production in the US at its first plant in Warren, Ohio, last August, with plans for its second in Spring Hill, Tennessee, to start operations next year. A third, in Lansing, Michigan, is expected to open in early 2025, with a total capacity between the three planning to reach at least 135 GWh.

CAM will play a critical role in ensuring GM has the raw materials to ramp production and hits its goal of building 1 million EVs by 2025. POSCO Future M president Kim Joon-Hyung says, “We are experiencing rapid growth of EV battery materials across North America,” adding:

I believe our joint venture will fortify its position in the secondary battery material industry with this proactive decision to increase CAM production and bring pCAM production to North America. POSCO Future M’s advanced technology and experience is supported by our expanding partnership with GM. We are aiming to play a key role in the eco-friendly mobility market with our products.

The Ultium CAM joint venture will help support the production of around 360,000 Chevrolet, Cadillac, GMC, Buick, and BrightDrop EVs between 2025 and 2030 in North America.

GM has several highly anticipated Ultium EV launches this year, including the following:

- Silverado EV: Deliveries to begin later in the second quarter, with production ramping in 2H 2023

- Blazer EV: Launching this summer

- Equinox EV: Launching this fall

After selling over 20,000 EVs for the first time in a quarter in Q1, GM lifted guidance with plans to produce 50,000 electric models in North America in the first half of 2023 and 100,000 in the second half of the year.

Author: Peter Johnson

Source: Electrek