Gates Carbon Drive, makers of belt drive systems found in the best-selling electric motorcycles on the market, has just launched a new version of its popular belt drive system.

Gates Carbon Drive Moto X9 launched

Gates’ newest belt drive system is known as the Carbon Drive Moto X9.

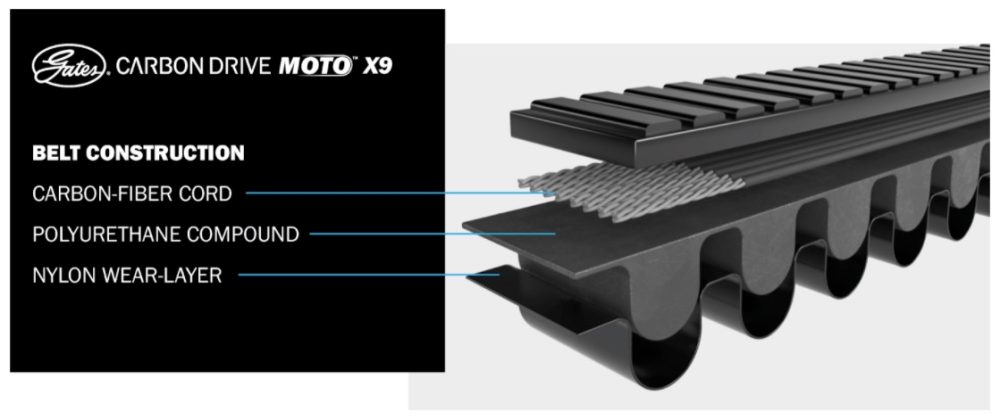

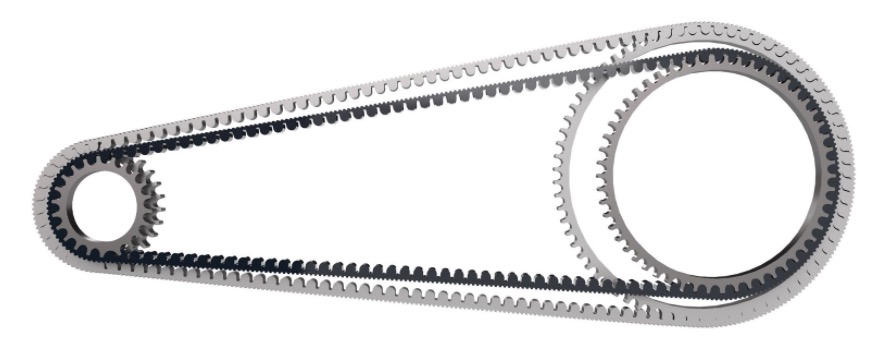

The new belt and sprocket design uses a novel setup that combines the Gates ultra-high tensile carbon fiber cord construction with a new tooth profile and pitch.

The updated 11 mm tooth profile now allows for a 9% narrower belt as well as a 10% smaller sprocket diameter. Those numbers sound small but actually have a large effect on the final design of vehicles.

While both the narrower belt and smaller sprockets will likely impact electric motorcycles by allowing for smaller final drive setups, that smaller sprocket diameter could be a game-changer in compact drive design.

In addition to the smaller size and lower weight, the new belt system also allows for up to an 84% longer service life versus its predecessor.

Gates shared a case study that shows how an 80 kW electric motorcycle manufacturer was able to switch from the former 14 mm tooth profile to the new Carbon Drive Moto X9 and gain a resulting 77% increase in available ratio.

That ultimately eliminated the need for any additional gear reduction, resulting in a direct drive setup straight from the high RPM electric motor to the rear wheel.

Another example shared by Gates showed how multiple electric scooter manufacturers using 3-10 kW motors were able to produce narrower drive systems using the updated Carbon Drive Moto X9 belt system.

The new design reduced bulk at the rear wheel, freeing up designers to become more creative with the e-scooter format.

As Gates General Manager of Mobility Joe Menzel explained in a statement provided to Electrek:

“For more than 40 years, Gates products have demonstrated the benefits of a durable, quiet, low-maintenance belt-drive over traditional chain-drive for all kinds of two-wheel applications, and we never stop innovating.

Moto X9 is our latest evolution designed specifically for personal and micro-mobility. Leveraging our materials science expertise and engineering advances, Moto X9 is stronger, allowing it to handle high torque with a narrower belt. With Moto X9, OEM engineers and product managers can specify more compact drivetrains on new or existing designs, optimizing packaging, saving production cost and enhancing their products’ performance and value for end users.”

Most electric motorcycles and scooters that use centrally mounted motors instead of hub motors rely on belts for final drives.

Belt drives last longer than chains, require less maintenance and critically are much quieter than chains.

Most gas-powered motorcycles produce enough engine and exhaust noise that the chain noise is lost in the mix. But with much quieter electric motorcycles, chain noise can be aggravating and detract from the experience.

For this reason, as well as the longer useful life of belts and lower maintenance, manufacturers of electric motorcycles such as Zero Motorcycles and Harley-Davidson employ belt drives on their bikes.

Many scooter manufacturers are also switching to belts. Gogoro, a leading Taiwanese electric scooter manufacturer, recently unveiled a new belt-drive setup after long using chains on its electric scooters.

Subscribe to Electrek on YouTube for exclusive videos and subscribe to the podcast.

Author: Micah Toll

Source: Electrek