Ford made a huge announcement Monday, revealing the Cologne Electric Vehicle Center is officially open for business. The new EV center is Ford’s first carbon-neutral plant and will be the home for its next-gen EVs, including the electric Explorer and an upcoming sports crossover EV.

Founded in 1930, Ford’s assembly plant in Cologne, Germany, has built nearly 18 million vehicles. Monday’s announcement marks a new era for Ford’s European operations.

As its first carbon-neutral assembly plant, the Cologne assembly plant will play a key role in the automaker’s transition to a sustainable future with EVs.

Ford first revealed it was planning to transform the facility, one of its largest manufacturing centers in Europe and home of Ford Europe, in 2021. The transition included winding down Ford Fiesta production to make room for its first “European-built, volume all-electric passenger vehicle” starting this year.

Since then, Ford invested $2 billion to transform the plant to prepare for the future of the auto industry – electric vehicles.

The first up will be the electric Explorer, based on Volkswagen’s MEB platform. Ford says the new mid-size electric SUV “combines German engineering with striking American style.”

Ford officially unveiled the electric Explorer in March, a five-seat family SUV expected to start at under $48,500 (€45,000). It will be the first EV produced at the facility, followed by an electric sports crossover, as it works to transform its brand in the region.

Ford plant opening a “fresh start” for EVs, auto industry

Federal Chancellor Olaf Sholz said the new EV plant “represents a fresh start,” adding, “This is good news for Cologne, for the auto industry in Germany, for e-mobility, and for the new era.” Bill Ford, executive chair, added:

Opening the Cologne EV Center is the start of a new generation of clean manufacturing and electric vehicles in Europe. This facility will now be one of the most efficient and environmentally responsible plants in the entire industry. I am thrilled to continue working toward a zero emissions future for our children and grandchildren.

The Cologne plant is expected to play a key role in hitting Ford’s target of building two million EVs annually by the end of 2026 with 250,000 annual EV production.

According to Ford, the Cologne EV center utilizes machine learning, autonomous transport systems, robots, and augmented reality to enhance production efficiency while improving over time.

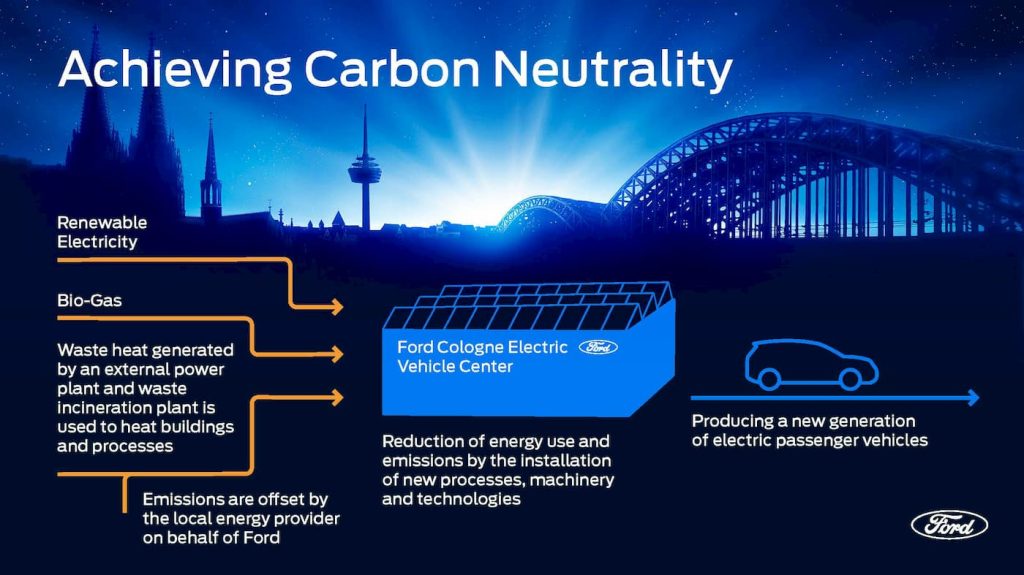

Ford is also using new processes, machinery, and technology to achieve carbon neutrality in addition to reducing energy use and overall emissions.

All electricity and natural gas required to operate the plant are carbon-neutral, with 100% certified renewable electricity and biomethane.

The heat is also carbon-neutral, with the local energy provider offsetting the emissions on Ford’s behalf. Ford says the heat is generated by an external power plant and waste incineration plant and supplied to Ford in a dedicated stream network.

According to Ford, the local energy provider plans to reduce operating emissions for heat delivery by around 60% in 2026, eliminating them entirely by 2035.

Once complete, the new EV center will be independently certified as carbon neutral, with audits on a regular basis.

Author: Peter Johnson

Source: Electrek