This week’s EV spotlight is on an automotive manufacturer that is by no means up and coming. Magna International has over 60 years of experience manufacturing auto parts. However, it is the company’s recent focus on electric mobility solutions and AI that has earned it an Electrek spotlight.

Magna International

Magna is a mobility manufacturer specializing in automotive components. Headquartered in Aurora, Ontario, north of Toronto, it is the largest automotive part supplier in North America and third-largest in the world. As previously mentioned, Magna International has over 60 years of experience innovating all aspects of vehicles. Interior, exterior, electronics, aerodynamics, and autonomy – Magna does it all.

As a contract manufacturer for other OEMs (original equipment manufacturers), Magna has designed and produced countless components for nearly every major automaker on the planet. They even manufacture complete vehicles for other OEMs that currently includes some electric vehicles in low volume. This includes New Entrant Fisker, for which Magna recently announced it will soon be producing an EV.

The company considers itself “a 64-year-old startup,” so Magna International applies its experience with big innovations to a startup mentality. As a result, it has not only found longevity with an international Rolodex of customers, but has remained of the forefront of new technologies, thanks to its research and development departments.

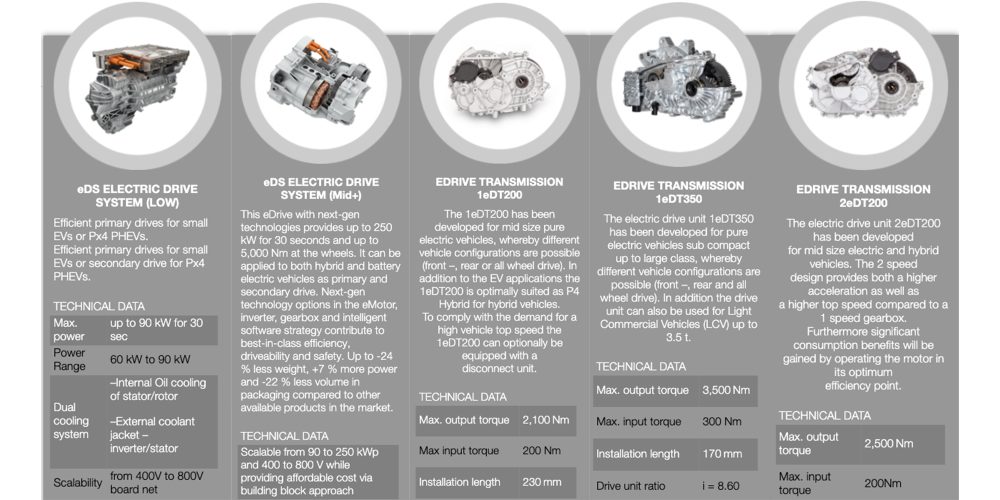

In the electrification of vehicles especially, Magna is developing unique and scalable solutions that target issues current OEMs face in terms of efficiency and cost.

Magna’s etelligentDRIVE solutions

Magna International’s Executive Vice President of R&D, Sherif Marakby, spoke with Electrek about the company’s current and future plans to accelerate vehicle electrification. When asked how Magna decided it was time to develop and manufacture electric solutions for vehicles, Marakby responded:

One of the things that we do at Magna is focus on a lot of automotive and transportation trends. So what are the growth areas of the business? Things like electrification and other technologies like driver assistance come to the surface very quickly. So we knew from a trend standpoint there were key technologies with a lot of projections around them. But to be honest, no one knows exactly what the volumes will be. How is this going to grow? How big is it going to be? And by what segment?

As an answer to these questions, Magna has taken a modular approach to its electric drivetrains. This helps keep its components adaptable to suit all its customers. Furthermore, it helps keep costs down, no matter whether the volume is for 5,000 vehicles or 50,000.

Furthermore, the modular approach allows Magna to work with its OEM customers to provide the most suitable configuration of electric drive(s) that best fit the vehicle. Whether it’s payload, towing capacity, or range, for example, Magna’s components can be added or subtracted purposefully.

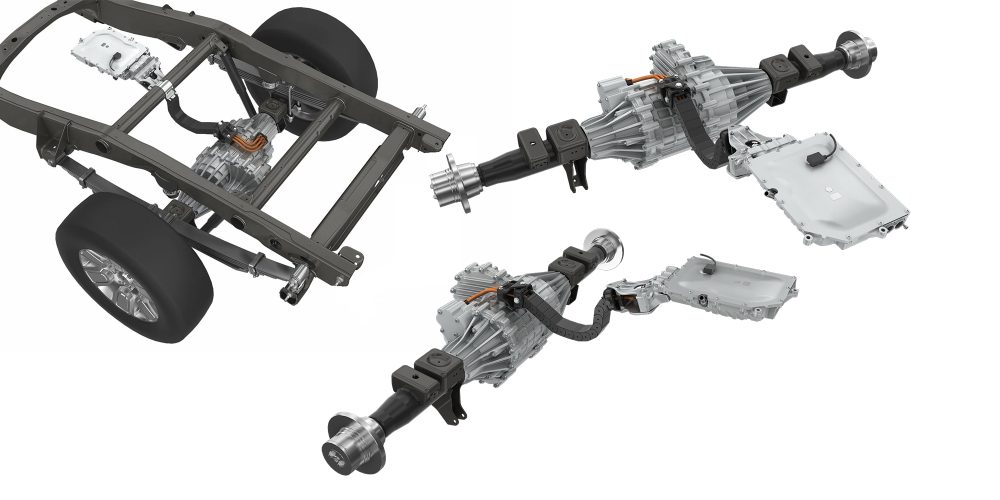

The Magna eBeam

One of the precursors to this entire spotlight for us was Magna’s recent announcement of its eBeam technology. eBeam is an electric axle drive system that can be dropped into an existing vehicle. Due to this design, eBeam can replace replace a traditional transmission and rear axle in a ladder frame chassis quite easily. Furthermore, the existing brakes, suspension, and chassis itself can stay as is. If you’re not familiar with the ladder frame chassis, it’s prevalent in most pickup trucks.

Magna International developed the eBeam with the goal of electrifying one of the toughest vehicles, the pickup truck. Sherif Marakby explained the eBeam to Electrek and how Magna approached the design:

The pickup truck market we all know, is a huge market in the US. But it’s also a market that is so focused on attributes – the towing, the capabilities of the truck are why people buy one. You can argue that a pickup truck is probably the last thing you want to electrify, because of those capabilities and battery electrics can get very expensive for a heavier vehicle. By having this modular approach, having the capabilities that this drop in replacement can provide, is so important to the pickup truck customer. We don’t think they can accept anything less.

This is a wise approach as boat-towing, horse-hauling pickup truck owners remain some of the toughest customers to sway toward electric. With that said, if automakers can deliver the same torque, payload, and towing capacity, the argument gets a little easier. Magna’s eBeam might accomplish that soon enough.

Magna International’s building block approach

What is further impressive about the eBeam is how modular it is. It can work in a lightweight truck, or a heavy-duty commercial vehicle, large battery, small battery, or even a hybrid. Magna calls this its “building block approach,” allowing OEMs to configure multiple drivetrain pieces together depending on the purpose of the truck.

Since Magna International is a parts provider to nearly all major automakers, the eBeam can one day be implemented on different-sized chassis with different size batteries. All existing behind the curtain of different EV automaker’s namesakes.

According to Marakby, the eBeam is still a few years away, but so far the interest level from OEMs has been “tremendous.” He elaborates:

That’s a pretty strong indication in the space that we’re a few years out, maybe less. But it’s such a promising technology in a tough segment. The consumer may not want too much change at the same time, but providing a vehicle with a component that can lend itself to an electric drive may be low volume in the beginning, but I’m convinced it’s going to take off.

We, along with a lot of pickup truck owners, will be watching the development of the eBeam closely. For now, you can view the full reveal explaining Magna’s technology here:

Magna International’s future

Looking ahead, Magna International looks to continue to develop and implement all of its automobile technologies. As for electric mobility solutions, Magna recently announced a joint venture agreement with LG to expand its powertrain electrification. Next, the biggest focus will be getting the highest efficiency and power density out of its products at the lowest cost.

In addition to electric powertrains, Magna is also quite fluent in autonomous driving and AI. The company is one of the few in the world to bundle radar, LiDAR, cameras, and domain controllers, and continues to steadily expand those capabilities. In fact, Magna-made ADAS products can now be found on more than 250 different vehicle models. Magna International’s Executive VP of R&D broke it down for us:

AI is already a part of our business in many ways, from employing it in our manufacturing facilities, to help with planned maintenance, to incorporating it in our vehicle technologies where it makes sense. For example, our connected eDrive systems leverage AI to predict and improve driving dynamics and efficiency, enabling the vehicle to predict changes in terrain and traffic situations and better manage battery usage for extended range. We also use AI as we continue to grow our ADAS L1/2+ business.

In developing driver assistance and AI technologies, Magna International truly is providing OEMs all components of a vehicle, inside and out.

Magna is by no means a startup, nor is it super-new to EV manufacturing. However, such a behemoth of a company is using its vast knowledge of manufacturing and research to help other automakers electrify their future vehicles more quickly and easily. Technology like the eBeam can certainly help accelerate that.

Subscribe to Electrek on YouTube for exclusive videos and subscribe to the podcast.

Author: Scooter Doll

Source: Electrek